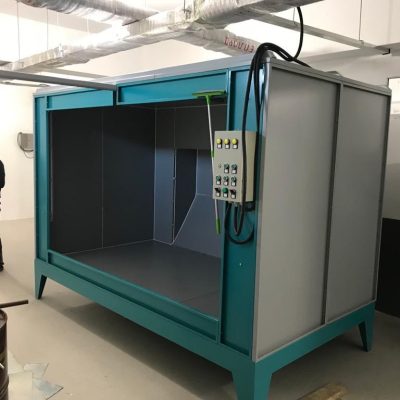

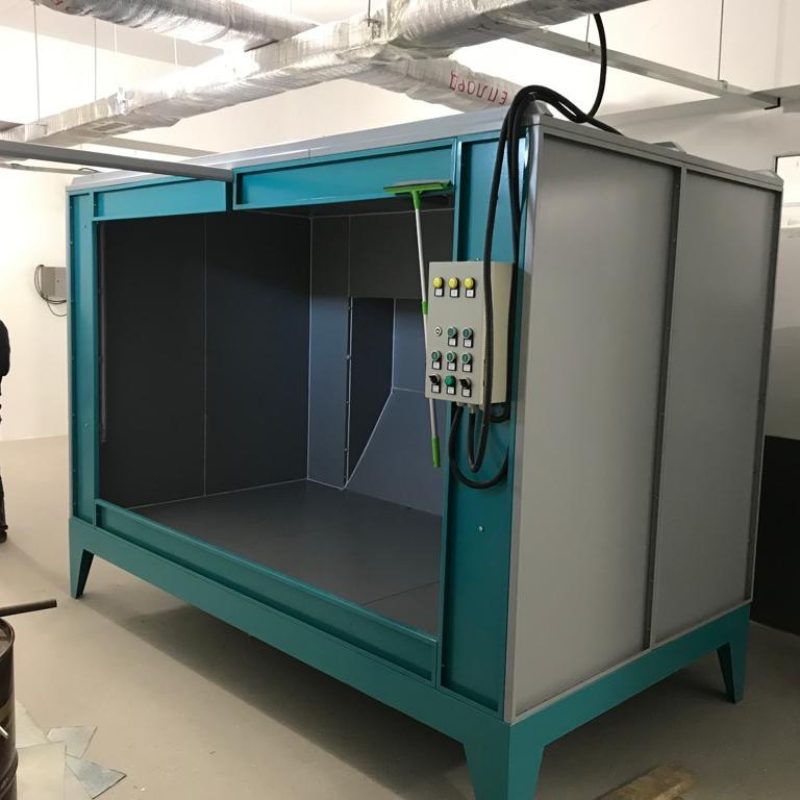

Standard Powder Coating Booths Filter Type

We produce and supply standard powder coating booths with cartridge recovery systems. It’s a reliable and cost-effective powder coating equipment for small business. Paint particles are not crumbled in this system, and the quality of the paint in re-use is not reduced.

8 standard models

Production time 30 days

Warranty period 12 months

Equipment delivery worldwide

You can order any standard model or customize equipment for your specific needs.