Description

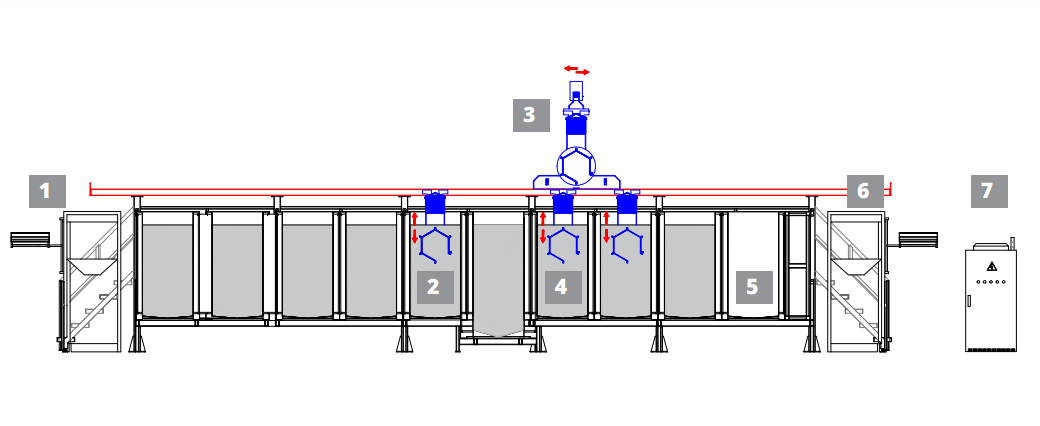

The process goes as follows: parts are loaded into special baskets within Dip Tank Lines. Then the parts are treated by being dipped in every process tank that takes a prefixed time period for each of the tanks.

Two of the surface treatment processes (i.e. Ironphosphate and Zincophosphate) can be done in dipping lines. The material basket within the loading section is loaded with the required materials.

After that, all you have to do is just select the program required for you from the control panel and press the start button. The basket is taken by the carrier robot into the loading area and placed into the first process tank.

Then the baskets are being dipped into the treatment baths for the required time and you need to wait until the processing time is complete. The basket is automatically taken by the robot upon the process time is over and taken into the next process tank. The last tank that completes the overall process is the drying tank. It’s role is the acceleration of the drying process of the materials coming out of the bath.

The basket is automatically left in the unloading section by the robot when the drying process timer runs out. Finally, the treated parts are discharged from the basket or drum through the discharge zone.

Characteristics

| Function | Surface cleaning |

| Features and benefits |

|

| Options |

|

| Parameters | Customized, produced according to customer requirements |

| Equipment of the line |

|