Description

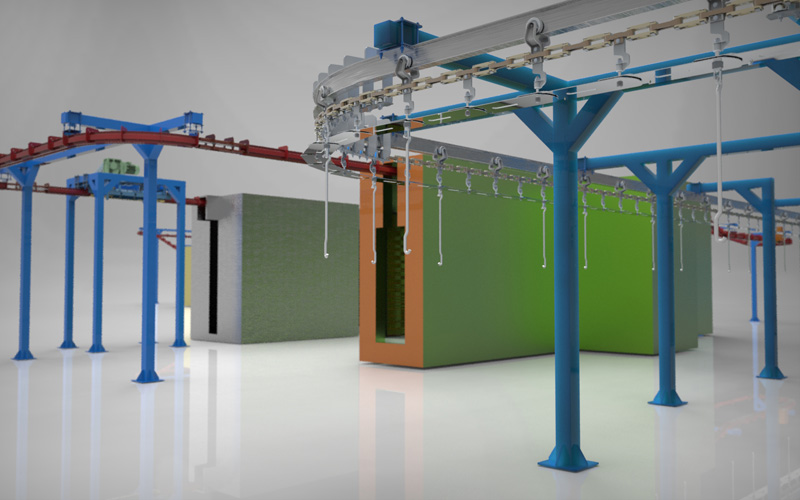

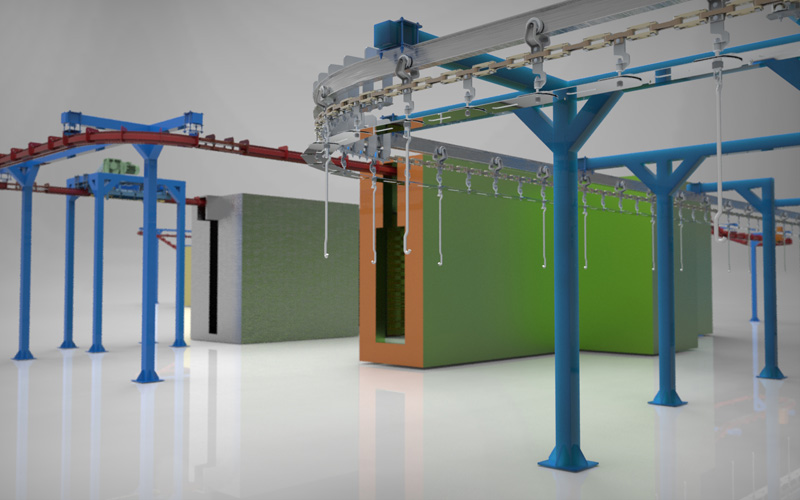

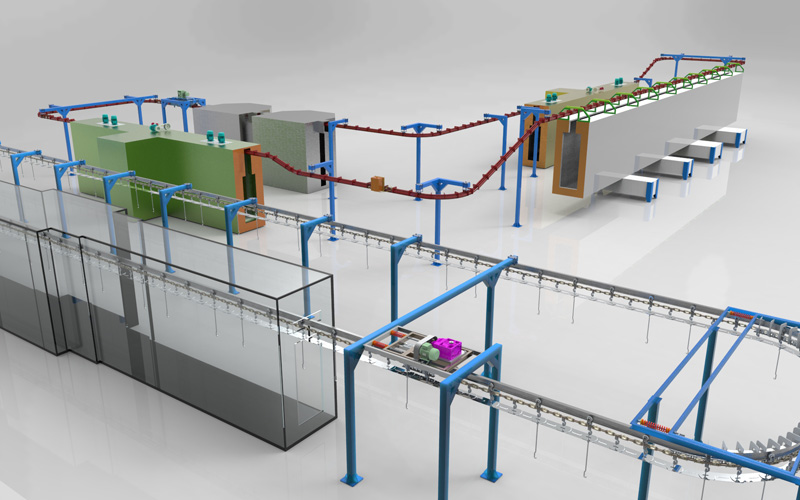

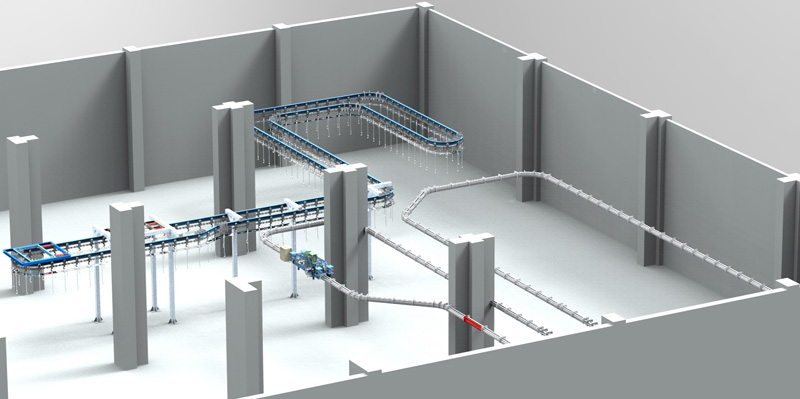

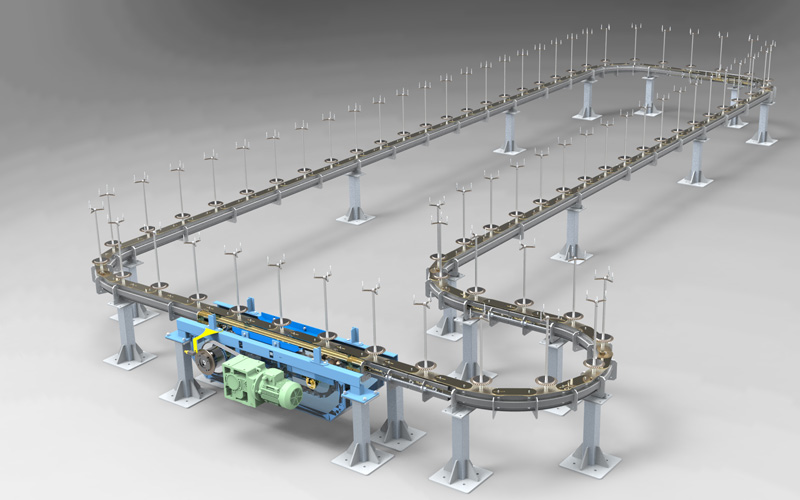

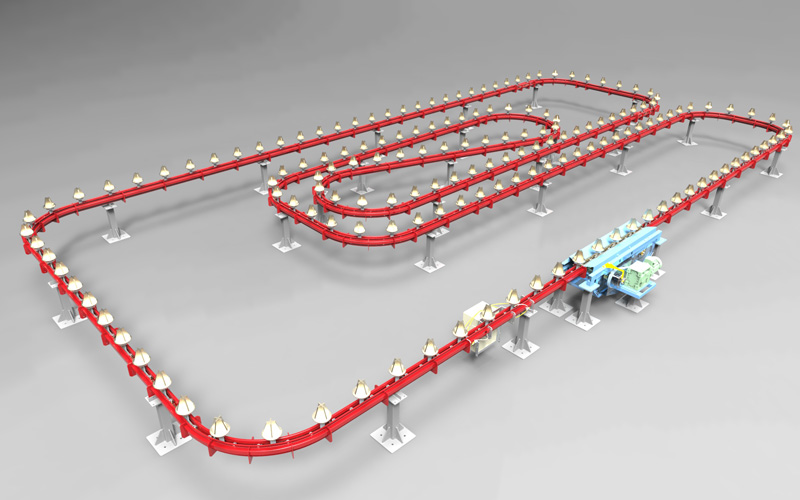

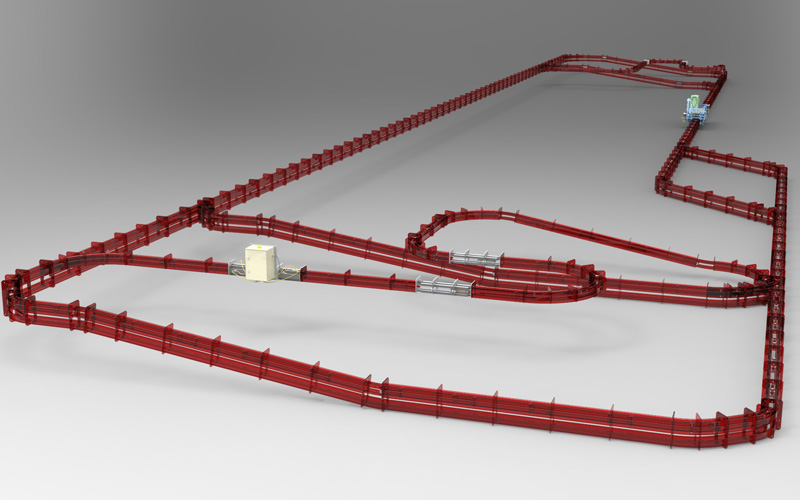

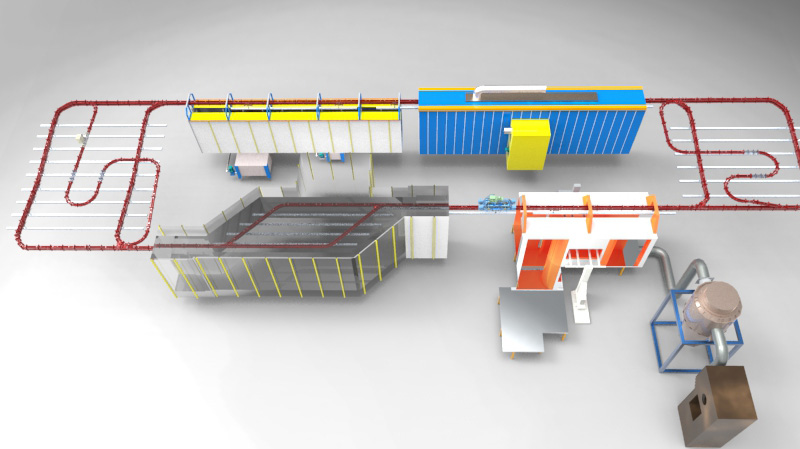

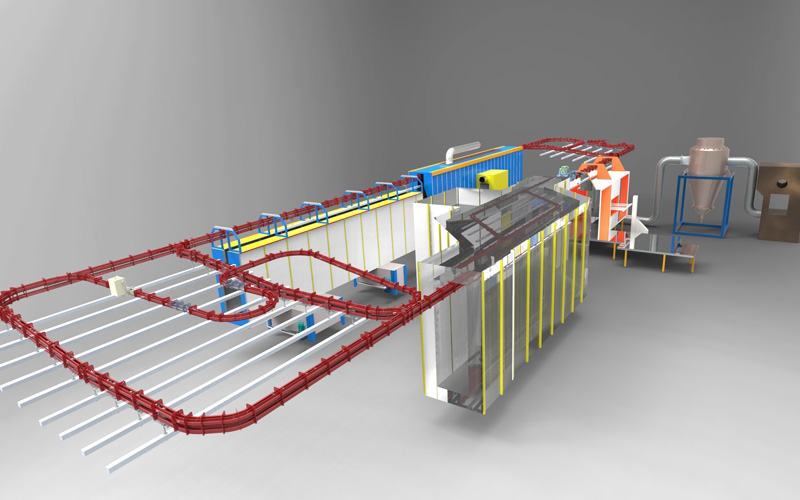

Conveyors with a 4-bearing group moving in closed guide rails are called Cardan type conveyors. These conveyors are preferred in facilities with their external appearance due to having vibration-free movement and automatic lubrication.

Silent movement is provided by the drive station. The damage to the drive motor from the conveyor breaking the circuit in the event of jamming is prevented by the torque limiter on the drive station. The electrical panel controls automatic lubrication of the system. Moreover, the speed of the system is controlled. There are different options of manufactured Cardan conveyors in terms of various load capacity per hanger.

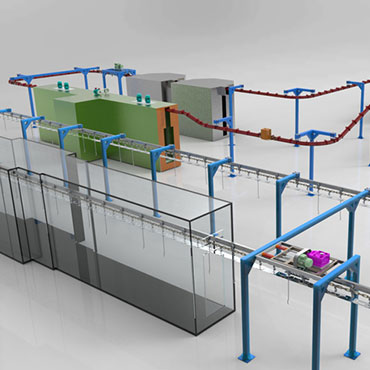

Our systems can be produced in different size options in order to satisfy any customer’s requirements and desire. However, it is made for extra price but the given price does not include trolleys.

Specifications

| Length | from 1 to ∞ m (According to customer requirements) |

| Conveyor Type | Cardan type |

| Carrying capacity | Calculated individually |

| Motor power | Calculated individually |

| Speed control | AC motor frequency inventor |

| Safety | Tork limiter |

| Adjustable conveyor speed | 0,5 – 3 m/min |

Working Principle

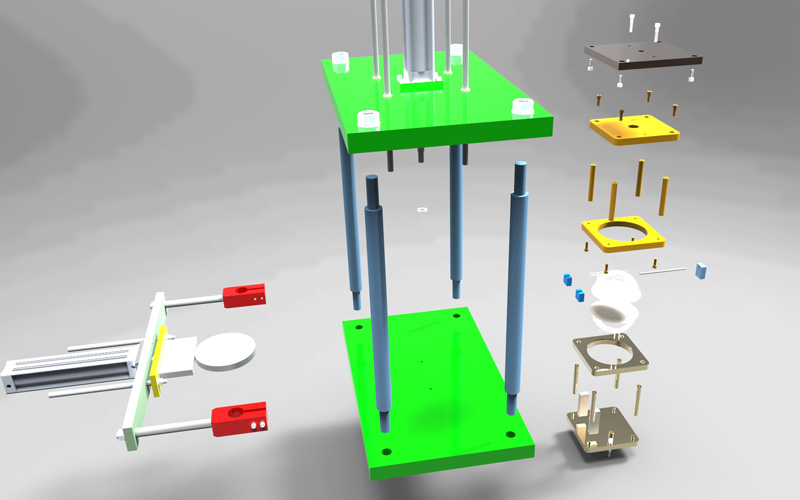

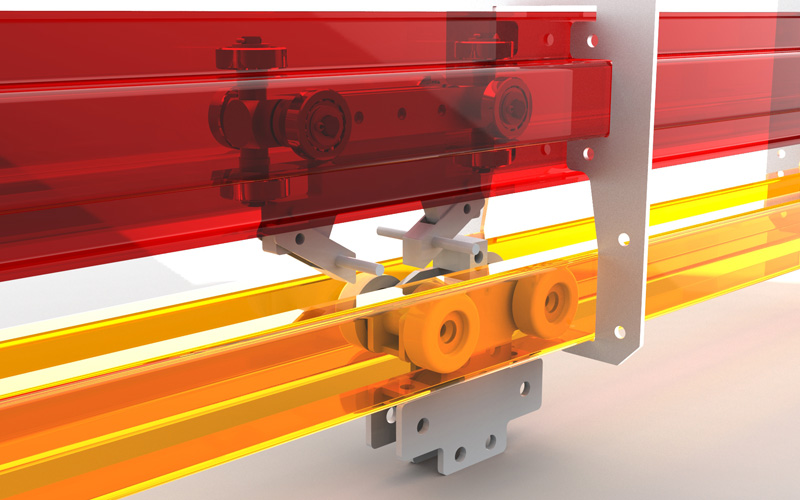

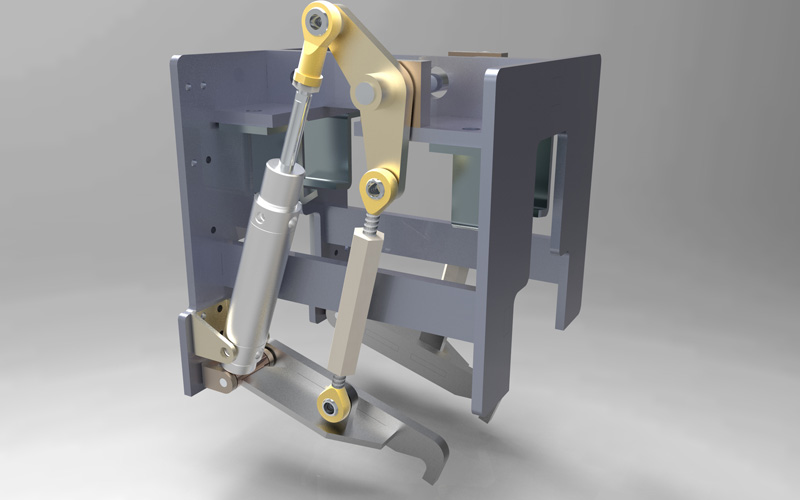

- Suspenders are connected to the carriage.

- The carriage is moved by a special reducer.

- The tire of transportation is made from a-shaped cross-section.

- Racks are made of a cross-section 80 x 120 mm.

- There are two buttons of an emergency stop: in a zone of loading and in a zone of a unloading.

Circuit

| Material | Steel, lead through thermal operation |

| Deterioration and extension | Are shown to a minimum |

| Additional elements | A gear for the extension |

Rails

| Material | ST 37 special flexible leaves |

| Width | 3 mm |

| Coating | A powder paint |

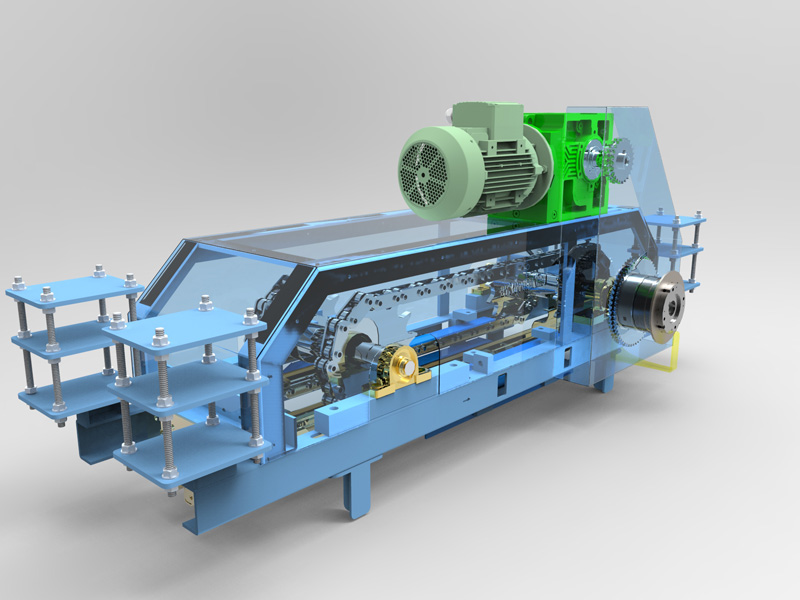

Extension gear and Driving Station

| Station of the extension | Consists of 2 designs which work adjacently |

| Portable pulley type | 4-pieces being on edges of a design |

| Movement | Provided by Portable pulley |

| Driving station type | Caterpillar type |

Moving unit

| Type | AC Inventor Frequency motor |

| Technology | Telemechanic |

| Functions |

|

| Mode setting | At an output from factory |

Lubricating System

| Type | Automatic |

| Functions | Grease of the conveyor’s bearings |

| Lubricant type | Special lubricant gear Festo |

| Principle of operation | Lubricant is provided only when the lubricant toggle-switch is on on the control panel and while conveyor is moving. It is possible to grease 4 bearings simultaneously. |