Description

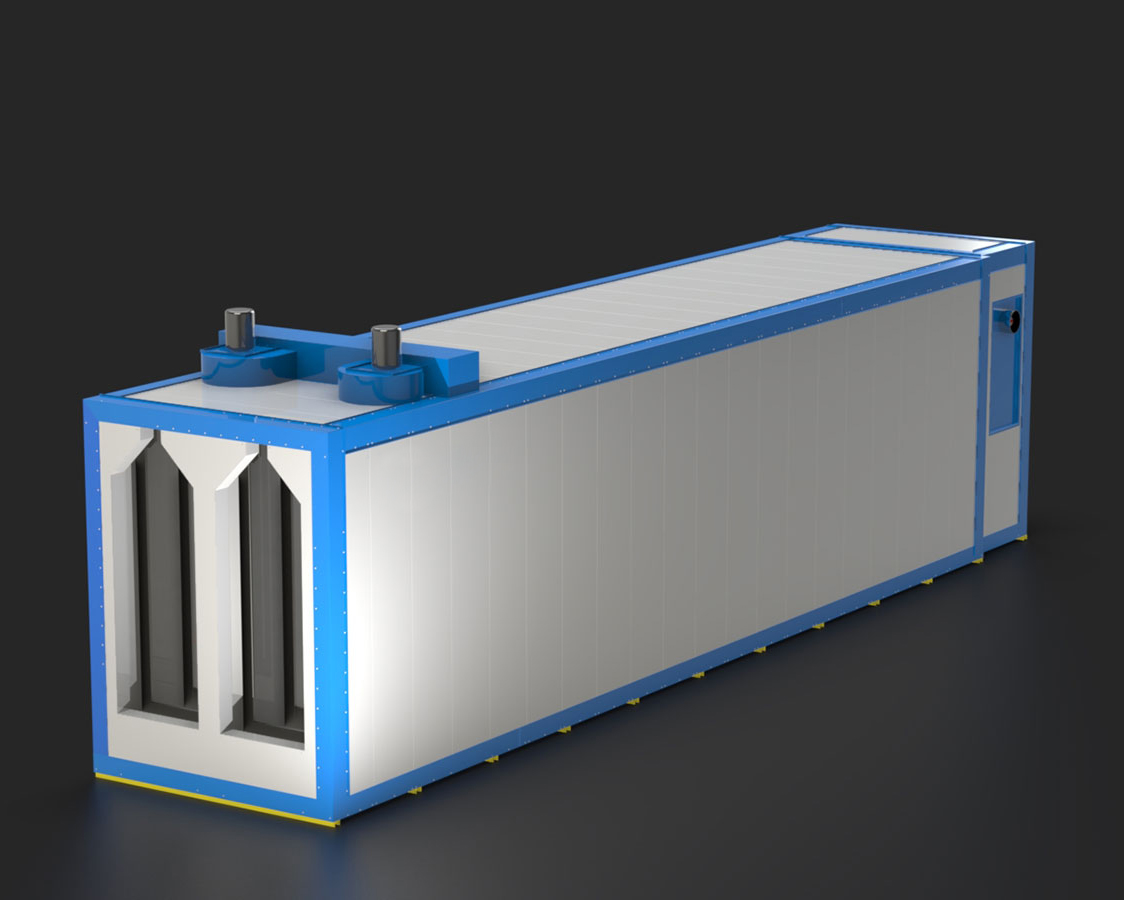

Such characteristics as insulation, power, capacity, etc. that we add to ovens within our own structure allow furnaces to provide customers with costs of energy use at a minimum level. Optimum energy saving is provided with specific parameters created by us while the automation and software developed by us provide the most suitable working conditions.

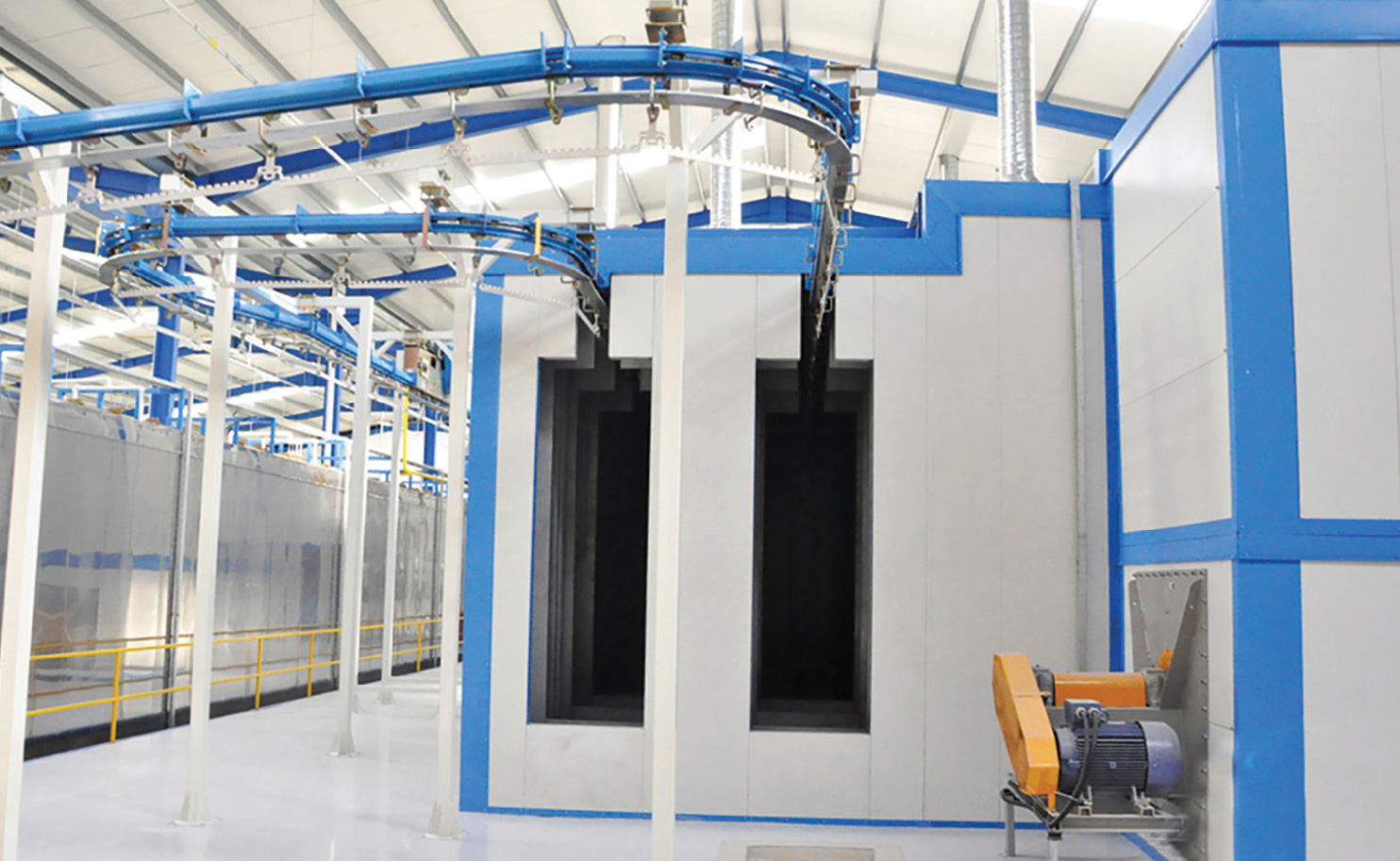

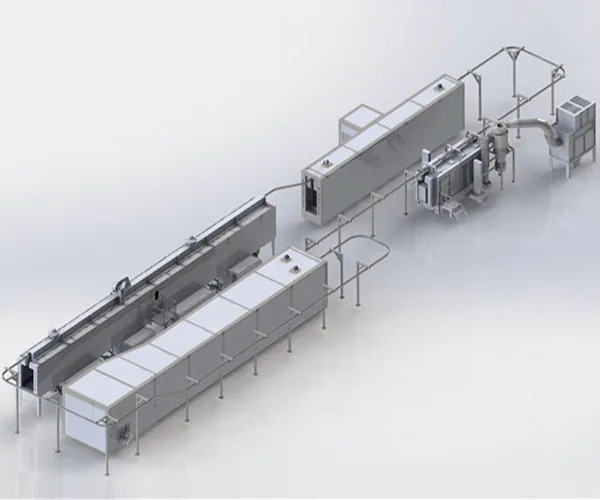

The most needed ovens for high volume industrial manufacturing applications are the U-Turn Continuous curing ovens. Their configuration creates conditions for higher production while leaving a relatively small footprint. At the same time, the heat is contained and the airflow is controlled more efficiently by them.

Our ovens can be produced in different size options in order to satisfy any customer’s requirements and desire.

Specifications

| Length | from 10 to ∞ m (According to customer requirements) |

| Height | from 2 to ∞ m (According to customer requirements) |

| Width | from 3 to ∞ m (According to customer requirements) |

| Heating Type | Indirect heating with thermounit |

| Heating Capacity: | Calculated individually |

| Circulation fans | from 2 to 40 kW (Calculated individually) |

| Heating | Electric, Natural Gas or Diesel |

| Insulation width | 150 mm (Insulation rockwool) |

| Exhaust fan | 0,55 kW( time can be regulated) |

Oven Body

| Material | Galvanized steel |

| Outside coating | DKP (powder painted) |

| Insulation | Rockwool 150 mm in diameter |

| Fixing furnace panels | Are mounted as an interlocking with high temperature resistant silicone |

Heating and Heat Exchanger

| Heating unit position | On the side of the oven |

| Heating unit operating temperature | 140 – 220о С |

| Thermoblock position | Vertically |

| Body of the heating unit insulation | 150 mm stone |

| Air ducts material | Galvanized sheet metal |

| Principle of operation | The dry hot air prepared in the heating unit is homogenously distributed into the furnace with the help of adjustable air ducts |

Heat Control and Burner

| Temperature control | Is done by digital thermostat |

| Thermostat operating temperature | Required |

| Thermostat operating range | Required |

| Burner operation | Automatically according to the set temperature |

| Burner control | The system software will be done in such a way that the burners will not work without the delivery fans running. |

Safety Thermostat

| Principle of operation | If the thermostat that controls the oven temperature or if the temperature rises excessively, it enters the circuit and disables the burner, allowing the alarm system to switch on. |

Exhaust Fan

| Function | Discharge the water vapor generated during the drying process |

| Operating time | Can be adjusted from the control panel and run automatically |

| Stop time | Can be adjusted from the control panel and run automatically |

Air Curtains

| Position | At the inlet and outlet of the furnace |

| Function | Heat loss minimized |