Description

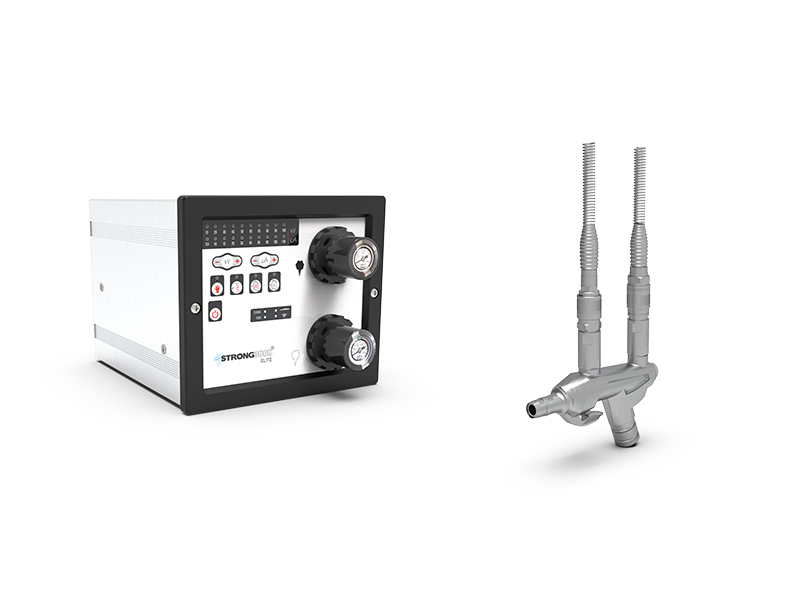

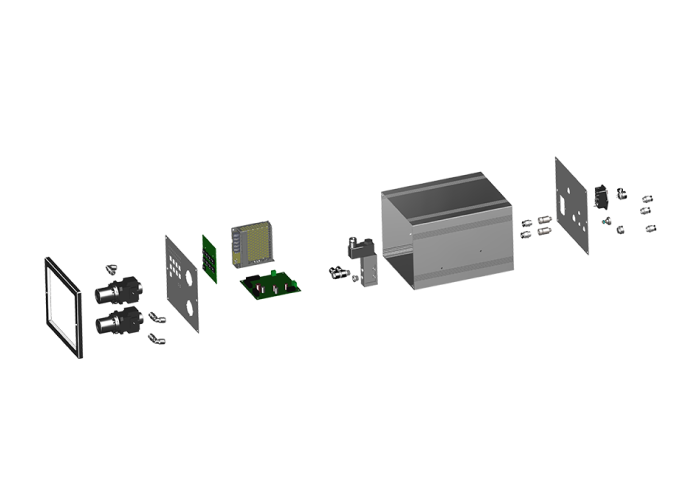

Our engineering team designed the new device of an elite class that provides the most advanced capability of enamel coating. The new enamel device of an elite class is manufactured with different head groups in mind, so that it could be worked with exceptional efficiency while being used within conditions of complex geometries and the most demanding environments. For this reasons, our device can offer the following benefits: it has plastic hopper and carrier that are easy to clean and it provides high coating performance in corner areas. Also, it includes Automatic Optimization System and renovated body design. Excellent distribution of dust is provided by wear-resistant spray nozzles. This is especially needed for products that are difficult for covering.

Main characteristics

- Microprocessor Controlled Mainboard

- Easy To Clean Plastic Hopper And Carrier

- Aos ( Automatic Optimization System)*

- Memory in 4 separate Modes

- Renovated Body Design

- High Coating Performance in Corner Areas

- RS485 modbus communication, memory identification, led warning system against earthing faults

Specifications

| Input voltage | 110-250 Vac (50-60Hz) |

| Weight | 35 kg |

| Max input pressure | 6 bar |

| Max air consumption | 350 Lt/ min (21 m³ / hour) |

| Powder box | 25 Lt |

| Powder capacity | 360 gr/min |

| Protection level | 1P54 |

| Operating temperature | 35°C max |

| Standard | EN 500-50 |

| Powder pipe sizing | 6,5mt / ø 12mm |

| Gun output voltage | 30-85 Kv |

| Gun output power | 30-120 µa |

| Gun powder capacity | 360 gr/min |

| Gun protection level | 1P54 |

| Gun weight | 420 g |

| Gun cable length | 5 m |

| Gun cable voltage | 32 Vds |